(一)Electroplating Process

Visual Effects

Electroplating ndiko kuiswa kwesimbi yakanyura pamusoro pesimbi kuburikidza ne electrolysis.Nickel plating inogona kupa iyo nameplate sirivheri - chena uye inopenya kupenya, ine yakanyanya kupenya, inonatsiridza magadzirirwo ese echigadzirwa uye ichipa vanhu hutete uye hwepamusoro-hwekuona ruzivo. Chrome plating inogona kuita kuti zita rezita riwedzere kupenya uye ziso - kubata, nekuratidzira kwakasimba, uye rinowanzo shandiswa kune nameplates emhando yepamusoro-yekupedzisira zvigadzirwa zvinoteedzera kutaridzika kwakanyanya. Uyezve, mavara akasiyana-siyana anogona kuwanikwa kuburikidza ne electroplating. Semuenzaniso, kutevedzera goridhe electroplating kunogona kuita kuti zita rezita rive nechitarisiko chegoridhe, richisangana nezvinodiwa zvemadhizaini chaiwo.

Kugara kwenguva refu

Iyo electroplated layer inogona kunyatso kuvandudza kushorwa kweiyo nameplate. Tichitora nickel plating semuenzaniso, iyo nickel layer inogona kutsaura iyo simbi substrate kubva kune zvinoparadza zvinhu zviri kunze kwezvakatipoteredza, senge unyoro, okisijeni, uye makemikari zvinhu, nekudaro ichidzikisa pasi oxidation uye corrosion rate yesimbi. Iyo chrome - yakapfava layer haina kuomarara kwepamusoro chete asi zvakare ine yakanaka kupfeka kuramba, kugona kurwisa zvikwambo uye mabrasions panguva yekushandiswa kwemazuva ese uye kuwedzera hupenyu hwesevhisi yezita rezita.

(二) Anodizing Process

Visual Effects

Anodizing inonyanya kushandiswa kune nameplates akagadzirwa nealuminium uye aluminium - alloy zvinhu. Munguva yeanodizing process, porous oxide film inoumbwa pane aruminiyamu pamusoro. Nekudhaya firimu reoxide, mavara akasiyana-siyana anogona kuwanikwa, kubva kune akajeka akachena mavara kusvika kune akapfava gradient mavara, ane yakakwira ruvara kugadzikana uye kuramba kupera. Mukuwedzera, kuumbwa kwepamusoro mushure me anodizing kwakasiyana. Zvichienderana nemaitiro, inogona kuunza matte kana semi-matte athari, ichipa vanhu hutete uye hwepamusoro-magumo ekuona chiitiko.

Kugara kwenguva refu

Iyo oxide firimu inoumbwa neanodizing ine yakanyanya kuoma uye kupfeka kuramba, iyo inogona kunyatso chengetedza iyo simbi substrate kubva pakupfeka. Panguva imwecheteyo, kugadzikana kwekemikari yefirimu yeoxyde yakasimba, inovandudza zvikuru kupikisa kwekuora kwezita rezita, zvichiita kuti ichengetedze kushanda kwakanaka pasi pemamiriro ezvinhu akaoma ezvakatipoteredza.

(三)Painting Process

Visual Effects

Kupenda kunogona kupa chero sarudzo yemuvara yemazita emazita. Kunyangwe iri ruvara rwakajeka kana toni yakadzikama, inogona kuwanikwa kuburikidza nekupenda. Uyezve, zvinoenderana neakasiyana pendi zvinhu uye maitiro, akasiyana gloss mhedzisiro inogona kuwanikwa. Semuenzaniso, yakakwira - gloss pendi inogona kuita kuti zita rezita ripenye kupenya, nepo matte pendi inoisa zita rezita rine yakaderera - kiyi uye yakapfava manyorerwo. Uye zvakare, yakakosha magadzirirwo emhando sechando uye kutsemuka mapatani anogona kuwanikwa kuburikidza nekupenda, kuwedzera iyo yakasarudzika uye yekushongedza hunhu hwezita rezita.

Kugara kwenguva refu

Pendi yemhando yepamusoro inogona kuumba firimu rakasimba rinodzivirira pazita rezita repamusoro, richinyatso kuparadzanisa unyoro hwekunze, okisijeni, uye zvinhu zvemakemikari, kudzivirira simbi kuti isaite ngura nekuora. Panguva imwecheteyo, pendi yepende inewo imwe dhigirii yekudzivirira kupfeka, kukwanisa kupikisa zvishoma zvishoma uye kudhumhana uye kudzivirira maitiro uye ruzivo rwemashoko pane nameplate kubva pakukuvadzwa.

(四)Brushed Process

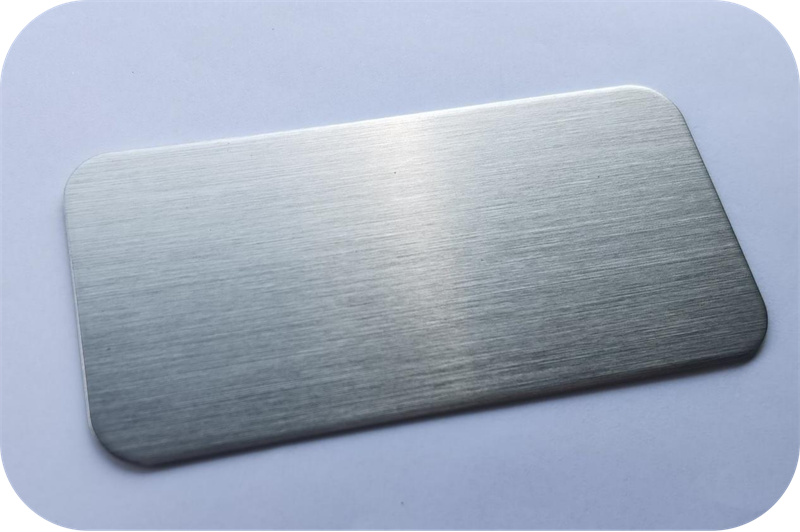

Visual Effects

TheBrushed process inoumba maunifomu filamentous textures pamusoro pesimbi pamusoro kuburikidza mechanical friction. Aya mameseji anopa zita rezita rine rakasiyana magadzirirwo, richiratidza rakapfava uye rakapfava simbi inopenya. Kana ichienzaniswa neyakatsetseka yepasi, iyo Brushed mhedzisiro ine akawanda akaturikidzana uye matatu-dimensionality, ichipa vanhu nyore uye fashoni yekuona chiitiko, kunyanya yakakodzera nameplates ezvigadzirwa zvinoteedzera chimiro chakareruka.

Kugara kwenguva refu

Kunyangwe iyo Brushed process ine diki mhedzisiro pakuvandudza kushora kweiyo nameplate, inogona, kusvika padanho rakati, kuvhara zvikanganiso zvakanaka uye zvikweshwa padenga resimbi, ichidzikisa njodzi yekuora inokonzerwa nekukanganisa kwepasi. Panguva imwecheteyo, kuomarara kwepasi mushure meBrushed kunowedzera zvishoma, kukwanisa kuramba kushoma kwezuva nezuva kupfeka kune imwe nhanho.

Mukupedzisa, maitiro akasiyana ekurapa epamusoro ane yavo yakasarudzika pesvedzero pane zvinoonekwa maitiro uye kusimba mune nameplate customization. Mune chaiyo nameplate customization process, zvinodikanwa kunyatso sarudza nzira dzekurapa dzepamusoro zvinoenderana nechigadzirwa, nzvimbo yekushandisa, uye dhizaini zvinodiwa kuti uwane yakanakisa kutaridzika mhedzisiro uye kusimba.

Kugamuchirwa ku quote yemapurojekiti ako:

Contact:info@szhaixinda.com

Whatsapp/foni/Wechat: +8615112398379

Nguva yekutumira: Feb-21-2025